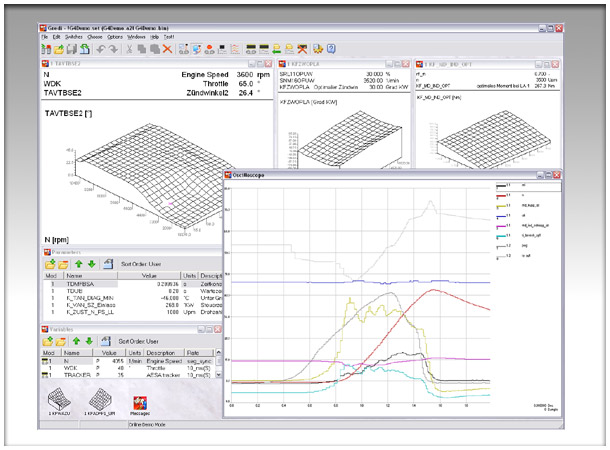

| All-in-one

All major functions required by an application

engineer are integrated into a single intuitive framework:

- Numeric and graphic calibration of

ECU maps and parameters

- display, recording and evaluation of simultaneously acquired

ECU internal and process data

- transfer, comparison and documentation of calibration

data (changes)

- flashing of ECU program and data memory

- monitoring of ECU communication.

|

| |

|

| |

| DriveRecorder |

| |

| The DriveRecorder is like a flight

recorder for your development or durability vehicle. Setup

is extremely simple: Just select the ECU data elements you

wish to record by double-clicking in online mode, and recording

starts instantly. MCS400 saves the ECU data elements to local

flash memory on a rolling data log - the PC can be disconnected

and reconnected at any time. You can then upload the data

and, evaluate and archive within Gredi V4 just as you would

conventional recorded data. |

| |

| Lower Total Cost of Ownership |

| |

One of the most attractive features

of Gredi V4 is that when you purchase MCS400 you receive Gredi

V4 as part of the package. There is even no expensive maintenance

contract, you get free software updates, free support via

email or phone and there are no software license fees for the standard

Gredi V4 software. Gredi V4 is evolving all of the time, with

new features being added and existing features being enhanced.

Customer specific extensions are possible, please contact

us in order to receive a quote. |

| |

| Slim and easy to use |

| |

| Gredi V4 runs under Windows 98,

NT, 2000 and XP and is designed to be as easy to use as possible.

Overwhelming featurism is replaced by a slim and smart function

set. Most configuration is done automatically, repetitive

tasks are simplified by retaining the previous system state.

Build-in expert knowledge tries to shield the application

engineer from tedious tasks. |

| |

| Responsive |

| |

| Launching Gredi V4, initialising

MCS400 and closing Gredi V4 all take just seconds. Gredi V4

is designed with large multi-ECU projects in mind, supported

by MCS400 as a stand alone computer with it's own Real Time

Operating System. |

| |

| Sophisticated error handling |

| |

| With Gredi V4's sophisticated

error handling, if your ECU resets, Gredi V4 will restore

the calibration data to the ECU. When Gredi V4 compiles your

ECU description files, if values are out of range or incorrect,

Gredi V4 will warn you and show you the line where the error

occurs. Error checking is performed strictly and self-healing

is done wherever possible, but unrecoverable errors are reported

directly to prevent fuzzy system behaviour. |

| |

| Network functionality |

| |

True network compatibility with

plug and play IP Configuration.

As the MCS400 can act as a DHCP server or client and with

our Plug and Play IP configuration, integration into your

company network should be simple. Or you can plug it straight

into your PC network port and because of the MCS400 feature

of auto selecting MDI / MDIX crossover, you don't even have

to change your network cable. You can even assign a specific

IP address to the MCS400 allowing the user to not only operate

the MCS400 over the company LAN but also over WAN connections,

i.e. over the Internet. |

| |

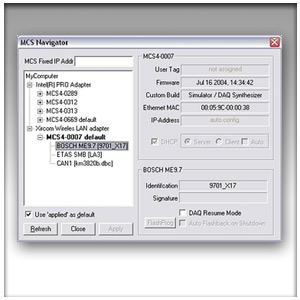

| MCS Navigator allows easy

Point & Click MCS Selection |

| |

|

To simplify networking Gredi

V4 has a graphical navigation window that allows you to identify

all MCS400's and ECU's connected to the network for point

and click selection. |

| |

| Industry Standards supported |

| |

Gredi V4 natively supports open

industry standard ASAP2 (ASAM-MC2) ECU description (.a2l)

files, as well as Intel Hex (.hex) and Motorola S-Record (.s19)

calibration data files.

Calibration data listings can be exported as DAMOS Format

(.dcm) files.

CAN database (.dbc) files are natively supported for ECU communication

monitoring.

Gredi V4 and DriveRecorder recordings can natively be stored

as Measure Data Format (.mdf) files, which provides a convenient

way of archiving data and a is a well established means of

data exchange in the automotive industry.

Gredi V4 provides high-level access to ECU data for e.g. test

bed systems via it's build-in ASAP3 Host Coupling Interface. |

| |

| Legacy support |

| |

| Gredi V4 still natively supports

the ECU description (.rob), raw calibration data (.bin) and

recording (.rec) files that previous Gredi versions used.

An upgrade path is provided by export features allowing exporting

of rob descriptions

to ASAP2 format and rec files to Measure Data Format. |

| |

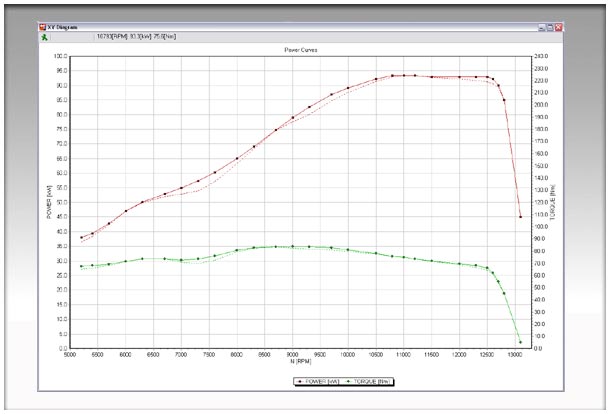

| XY Diagram |

| |

"Power Curves" and other non

time based charts can be built using the XY Diagram, the XY

Diagram is also useful as a real-time working point monitor.

The chart is build by sequentially driving the engine on the

testbed through all workpoints and triggering the

measurement for ever workpoint.

The trigger channel controls the sampling and storing of

averaged online values into the XY Diagram. Modes of

operation are:

- Start manually, store value after averaging time.

- Start via trigger channel, store value after averaging

time.

- Trigger channel starts and stops averaging, store value

afterwards.

- Continuously store values after averaging time.

Erroneous data points can be easily removed.

The "Load Reference File" allows a before/after comparison

of e.g. optimizing attempts.

Up to 4 Y-axes are possible |

| |

| Calibration Data Listing function |

| |

| Calibration data listing allows

you to create readable listing files of all or selected elements

for documentation and data exchange purposes, mainly exported

to different text file formats. The list of selected elements

can be saved to and read from a disk file. |

| |

| Calibration Data Transfer

function |

| |

| Calibration data transfer allows

you to transfer all or selected elements to a destination

calibration data file for upgrading and merging purposes.

Different ECU description files for source and destination

are allowed and the transfer is made via the physical (engineering)

model, even map dimension changes with linear interpolation

are supported. The list of selected elements can be saved

to and read from a disk file. |

| |

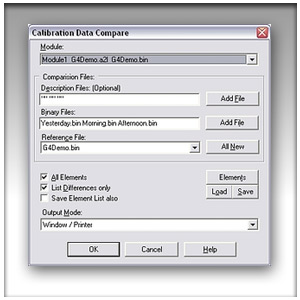

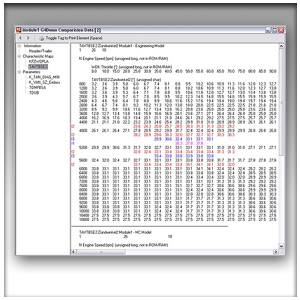

| Calibration Data Compare functions |

| |

|

Calibration data compare allows

you to visualize the differences between up to four calibration

data files. Different ECU description files are allowed and

the comparison is made in the physical (engineering) model.

The comparison result can be viewed on screen, printed or

exported to different file formats. The list of selected elements

can be saved to and read from a disk file. |

| |

| Another kind of compare function

jumps in whenever calibration data changes are present and

you are about to close Gredi V4: You can review all changes

made and accept or decline each change individually on a per-element

basis. |

| |

|

|

| |

| Simultaneously talk to 20

target devices (modules) |

| |

| With Gredi V4's ability to interface

to 20 target devices on 2(4) CAN busses and 2 Multi Mode Serializer

Ports simultaneously, you can control, calibrate and monitor

not only ECU's, but pseudo ECU's i.e data acquisition sub-systems

and Rapid Prototyping Modules (RPM). |

| |

| ECU communication monitoring |

| |

| ECU communication can be monitored

either as trace dump or in sorted listview style. By means

of CAN database (.dbc) files, raw communication packets can

be decoded into easy readable form. |

| |

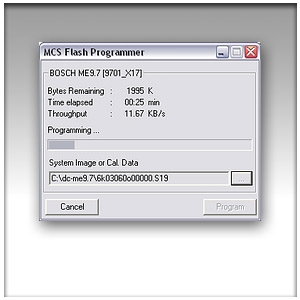

| ECU flash programming function |

| |

|

The flash programming window

shows ECU data and Flash file data as well as the progress

monitor. |

| |

|